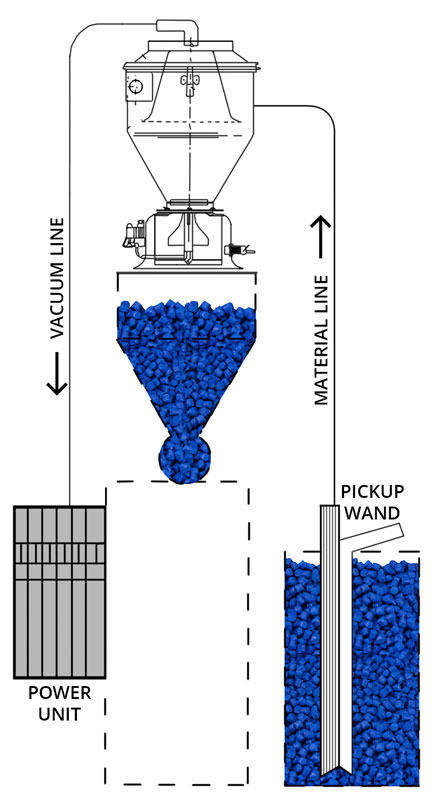

The Colourmate FL-110 is a unique trouble free loading system for plastic processors. It has been designed and developed to completely eliminate the inherent problems associated with filter cleaning or changing in more conventional loaders. The FL-110 system comprises a filterless, screenless loading chamber which is mounted on the processing machine hopper. The loading chamber is designed with a super efficient internal bell cyclone dust separation device which eliminates maintenance on this normally hard to reach component. Vacuum power is supplied to the loading chamber from an accessible power unit which is bracket mounted. On the side of the machine or on an adjacent wall for easy maintenance. The power unit is equipped with a heavy duty vacuum motor, cyclone separator motor protection filter with motor brush maintenance signal lights and solid state dual cycle control.

The FL-110 system includes:

- 1 cu. ft. material receiver with automatic level control

- Bracket mounted power unit with controls

- Adjustable pickup wand with handle

- (2) 10 ft. lengths of H.D. vacuum hose

The FL-110 system advantages:

- No more on machine maintenance

- Lightweight vacuum receiver

- No filter cleaning required between colour changes

- No moisture laden compressed air required

- No deterioration of vacuum power due to clogged filters

- Accessible controls and separation system

- Low cost motor protection filter

- Motor maintenance schedule signals

Features:

- Bell shaped material air separator

- Cyclone dust separation in power unit

- Most powerful Ametec vacuum motor available

- 24 volt level control for safety

- Electrics 115v 15amps

- Conveying rate-to 950 lbs./hr. (depending on lift/material)