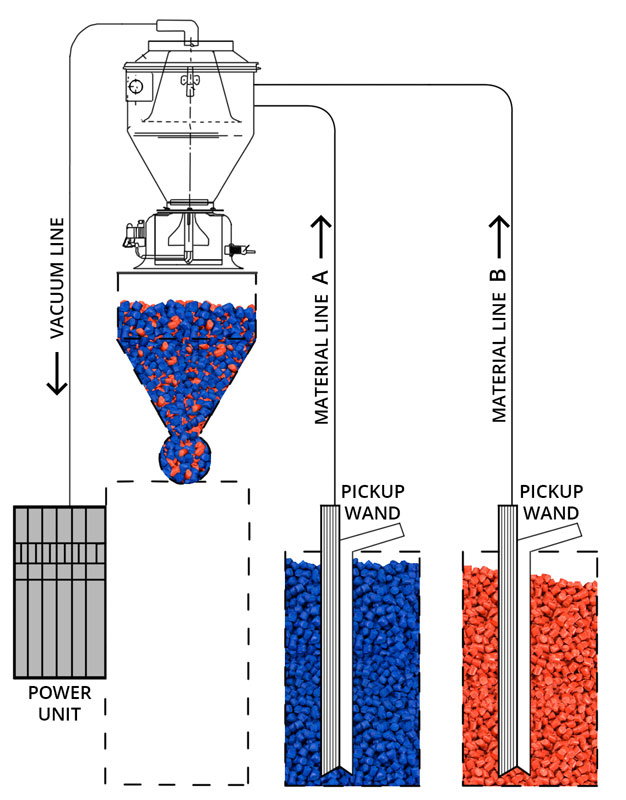

TWO MATERIAL VACUUM LOADING SYSTEM - PROPORTIONAL

- The Colourmate FL110P is a unique, trouble free, vacuum loading system for conveying plastic pellets and regrind. Reground plastics often contain filter clogging dust particles which will reduce the efficiency of conventional loaders. The FL110 has been designed and developed to completely eliminate the inherent problems associated with 'on the machine filter cleaning or changing.

- The FL-110 system comprises a filterless, screenless loading chamber which is mounted on the processing machine hopper. The loadingchamber is designed with a super efficient internal bell cyclone dustseparation device which eliminates maintenance on this normally hard to reach component. The chamber's discharge mechanismconsists of a pneumatically operated stainless steel cone which provides a very positive vacuum seal, even with dusty regrind or pellets with high static electricity.

- Powerful Vacuum suction is supplied to the loading chamber froman accessible vacuum power unit which is bracket mounted on the side of the processing machine or an adjacent wall for easy maintenance.

- The vacuum power unit is equipped with a heavy duty vacuum motor,cyclone dust seperator, motor protection filter, reliable solid state duel cycle control, and percentage timer control for proportional loading.

The FL-110P system includes:

- 1 cu. ft. material receiver with automatic level control

- Bracket mounted power unit with controls for conveying and proportioning two materials

- Two - Adjustable pickup wands with handles

- 30 ft. of H.D. vacuum hose

ADVANTAGES

- Less risk of employee in jury from falls

- No filter = No more on machine maintenance

- Lightweight loading chamber

- No filter cleaning between colour changes

- No filter blow-back required = no problems from moisture laden air

- No deterioration of vacuum power due to un maintained filters

- Accessible controls on vacuum power unit

- Keeps employees safe by eliminating on machine maintenance

FEATURES

- Made in Canada

- Adjustable timer controls vacuum on/off loading cycle

- Bell shaped material/air separator

- Cyclone dust separation in power unit

- High CFM/Suction Vacuum motor for superior performance

- 24 volt level control for safety

- Conveying rate- to 950 lbs./hr. (depending on lift/material)

- Two pneumatically operated tangential material inlets

- Ground Accessible vacuum power with adjustable percentage timer for mixture control of two materials

- Dependable Canadian made proximity switch for level control

Keep you employee safe from harms way.

Filterless means less maintenance in elevated situations = less risk of injuries from falls.

Filterless means less maintenance in elevated situations = less risk of injuries from falls.